About Us

WHO WE ARE

The Aardvark Group was founded in the UK in 1982 as an OEM of Protective Mobility vehicles and whilst over time the organization has added entities in both the US and the Middle East, the Group remains very proudly a British defence and security organization.

Fundamentally Aardvark develops solutions on the ‘defensive’ spectrum and to that end we do not manufacture, nor supply lethal products.

In the early days of the business, Aardvark’s core Protective Mobility product was the globally adopted Joint Service Flail Unit used by military and NGOs across the globe for breaching and route proving in a combat engineering scenario and the clearance of area contaminated by land mine and improvised explosive devices.

Aardvark is prolific in the history of combat engineering, receiving accolades and awards including being awarded the title, “The Most Effective Landmine Clearance System in the World” by the Sixth Secretary General of the United Nations, H.E. Boutros Boutros-Ghali, in 1993 through his own personal experience of our equipment in the clearance of vast areas of contamination in Egypt.

Following a strategic review involving our primary clients, government, strategic partners and supply chain in 2017 the Aardvark Group invested in significant expansion which delivered mission critical capabilities in Defence and Security, and the ability to develop novel integrated technical solutions, designed to protect people and assets from harm – both capabilities supported by a network of colleagues drawn from military and policing communities on 4 continents.

The outcome of these two critical enhancements to the Aardvark Group is an unmatched access to a vast network of partners who collaborate with us through their complementary technology, services, training and solutions.

- Proven Track Record: With 40 years of experience, the Aardvark Group has consistently demonstrated excellence in delivering protected mobility solutions tailored the specific needs of the end-user, from border security and defence to the clearance of the remnants of war and combat engineering in over 50 countries globally.

- OEM In-House Design and Testing: Our in-house capabilities ensure the precision design and rigorous testing of our solutions, guaranteeing superior performance and safety.

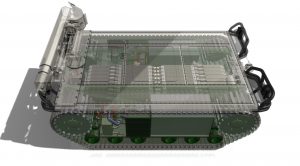

- Class Leading Portfolio of Products and Solutions: Crewed and Un-crewed Vehicles and the advancement into Ai: Aardvark’s crewed platforms, Cerberus and Hercules are class leading. Aardvark’s uncrewed ground vehicles, GEN2 and RANG-R are leading the chase in the transition from operator driven vehicles to autonomous systems.

- Other OEM Approved Engineering Centre: Alongside our Aardvark OEM developed solutions we are also an accredited engineering centre which brings prestige and an unparalleled expertise to enhance the capabilities of our end-users heavy machinery fleet whilst maintaining the technical ability of the equipment and protecting the OEM warranty.

- Training: The Group controls the delivery of all end-user training in-house ensuring an exceptional level of qualification and proficiency, and that delivers the highest equipment utilisation in our sector – further enhancing and protecting Aardvark brand.

- Lifecycle Maintenance Support: Uninterrupted support through our operations centres across the globe.

News & Events

Explore our stories from around the world

AGRI-robots

https://aardvark.group/wp-content/uploads/2024/05/Agri-short-edit.mp4 AGRI-robots Robotics has recently emerged as one of the most exciting and promising technologies in the agricultural sector. Driven by population growth and

the Aardvark Group Leads the Charge in AI and Autonomous UGV Advancements

The Aardvark Group is at the forefront of pushing technical advancements in autonomous Unmanned Ground Vehicles (UGVs), with a primary focus on replacing legacy systems

Military transition experience – James Young

The transition from military life to civilian can vary greatly from person to person. The Aardvark Group first spoke with James when he was still